Test equipment management

Calibration, availability and verification – all digital.

KENEXOS® – test equipment under control. Safe, documented, ready for use.

Home | Solutions | Building and facility management | Test equipment management

The challenges of test equipment management

The problems

Whether measuring devices, calibration tools or safety-relevant equipment – an overview of test equipment is essential for companies and operators.

In practice, however, central directories are often missing, inspection deadlines are overlooked, calibrations are not verified and devices used are not ready for use in case of doubt.

This jeopardizes process reliability and entails legal risks – especially in certified or safety-critical areas.

No central overview of available test equipment

Missed calibration or test intervals

Insufficient or even missing proof of test status and history

Uncertainty about operational capability and responsibilities

High manual effort for administration and documentation

Risk of complaints during audits or certifications

The solution

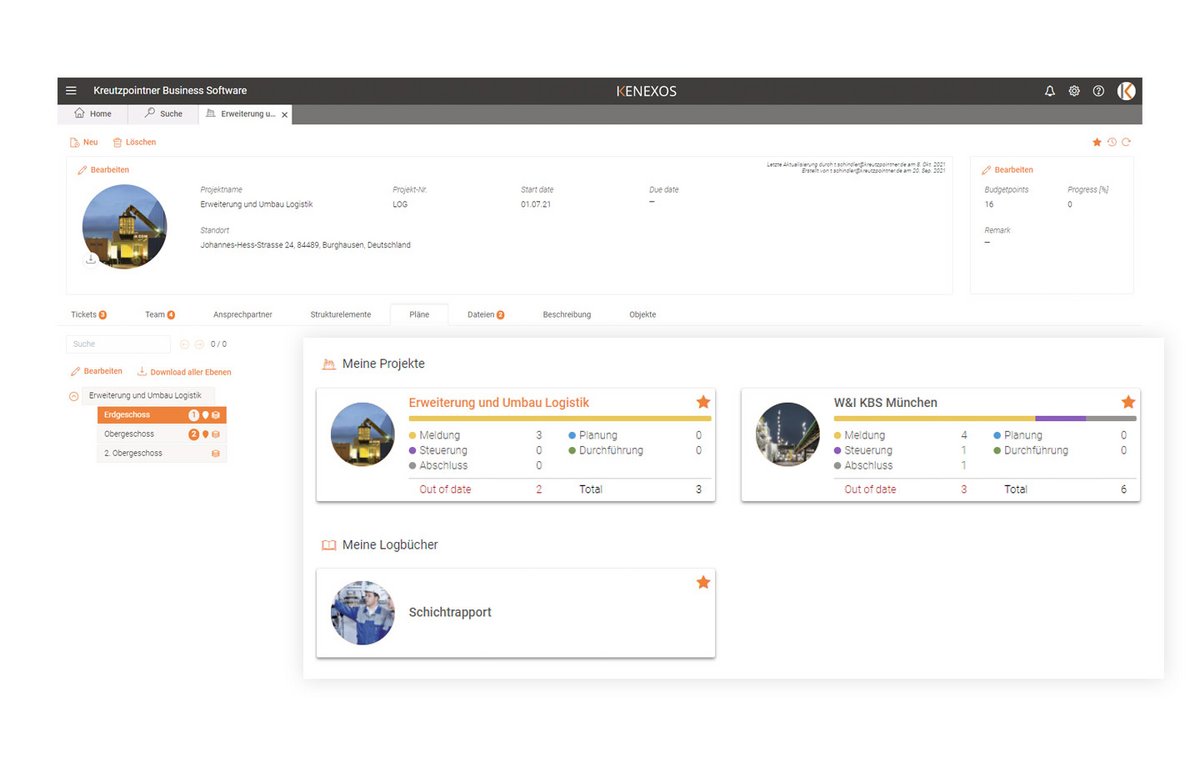

KENEXOS® manages your test equipment digitally, systematically and audit-proof.

Each device has its own digital file – with master data, inspection intervals, history and status display.

Pending tests are automatically displayed, documented and evaluated.

This gives you full control over all the test equipment used – at any time and from anywhere.

The advantages of KENEXOS®

Digital test equipment file with history, status and availability

Automatic reminder of calibration and test dates

Audit-proof storage of all test and calibration certificates

Integration with maintenance, laboratory management and plant management

Mobile recording and verification by technicians

Audit and certification-compliant documentation

Test equipment management is quality management

Test equipment management (also known as test equipment management, PMV) is part of quality management. It aims to ensure and maintain the quality, reliability, usability and readiness of test equipment in a company. Through monitoring, test equipment should be able to provide the required performance at all times. Test equipment management is therefore a method for increasing process capability.

Chapter 7.6 of the EN ISO 9001:2008 standard requires the introduction of a process that ensures the suitability and functionality of the test equipment.

In summary, test equipment management organizes the procurement, use and monitoring of test equipment.

Your solution for asset management

The right module

- Optimized for operators and service providers

- Centralized and detailed storage of technical documentation

- Mobile use via computer, tablet or smartphone

- Digitization and automation of manual routine work

- Integration of all internal stakeholders and

external service providers and contacts

KENEXOS® EAM

Asset inventory, IoT integration, maintenance and fault management, test equipment/spare parts management, asset history, life cycle, compliance management, helpdesk, photo documentation, reports

Crucial for manufacturers

The reversal of the burden of proof in producer liability requires the manufacturer of products to test safety-relevant features, document the result and also provide evidence that the test equipment used is also subject to regular monitoring.

Without test equipment monitoring, manufacturers would not be able to prove in the event of damage that everything in their power was done to prevent the product from failing. Although test equipment monitoring alone is not sufficient, without it this proof can never be conclusively provided.

Advantages and possibilities of test equipment management with KENEXOS®

- Recording of your test benches and test stations as higher-level objects – including their exact location (building, room number, etc.).

- Recording of test equipment as objects including the associated test bench.

- Resubmissions for all necessary work and test steps such as visual inspections, calibrations, metrological checks, etc.

- Direct assignment of all relevant documents and instructions to your test equipment (e.g. operating instructions, test instructions, etc.).

- Direct assignment of all relevant processes (invoices, contracts, etc.) to each of your test equipment.

- Recording of all relevant information on the respective test equipment such as procurement date, serial number, manufacturer, purchase/lease/loan, etc.

- Automatic resubmission and reminder of upcoming test steps with defined lead time including your individual and digital test report.

- Internal/external service provider directory with assignment of the relevant persons and assignment of these service providers to test equipment (measurement technology).

TEST FREE OF CHARGE

Choose KENEXOS® today

Test all functions

14 days free of charge without restrictions!

Use the app immediately

on the computer, tablet or smartphone

Completely risk-free

Your access ends automatically!