Fault detection

Seamless communication. Fast response. Smooth operation.

KENEXOS® – Clear and structured recording of faults.

Home | Solutions | Building and facility management | Fault logging

The challenges of fault detection

The problems

Malfunctions, incidents and special events occur in technical systems and buildings on a daily basis.

However, there is often a lack of structured, centralized recording: reports are lost, remain incomplete or are not transferred correctly.

Reports are made verbally or on paper – which leads to loss of information, delays and repeated errors.

Faults are reported late or not at all

Lack of details on the type, cause and effect of the fault

No structured handover between shifts or teams

Unclear responsibilities in the event of escalations

Lack of transparency for management and maintenance

The solution

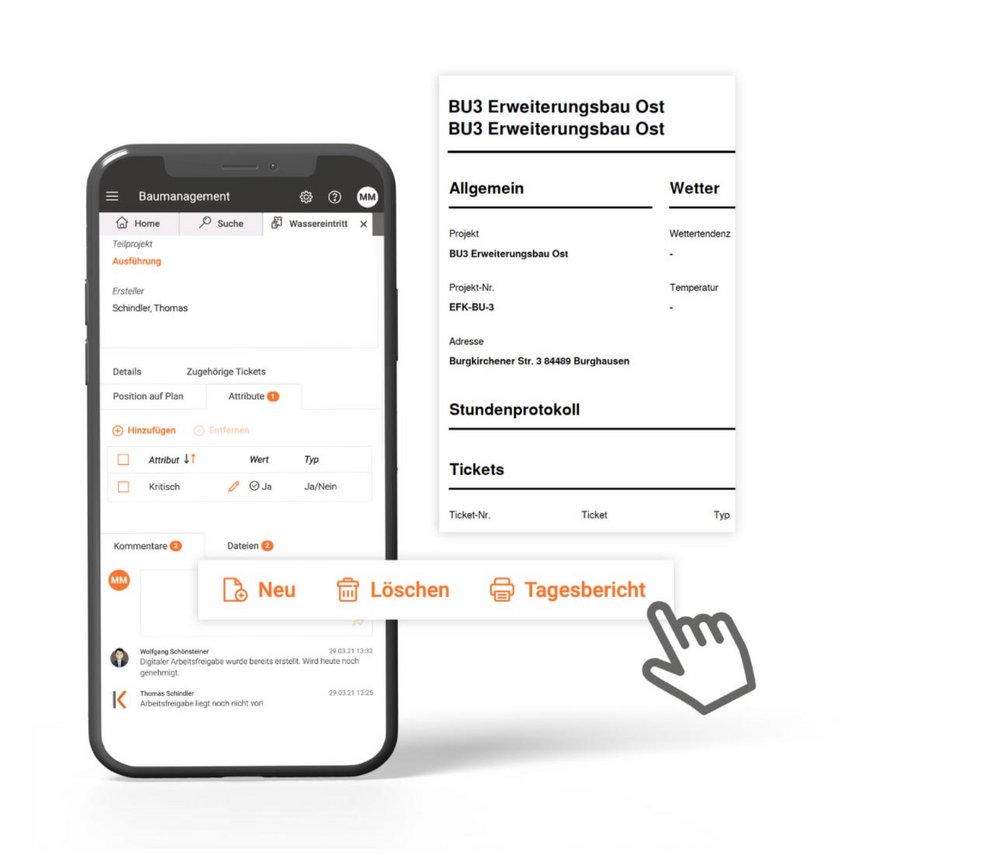

With KENEXOS® , employees record faults directly and digitally – including description, time, photos, measures and responsibilities.

All entries are immediately available in the system and can be prioritized and forwarded.

Managers and maintenance teams maintain an overview at all times and can react immediately.

The advantages of KENEXOS®

Digital fault recording via app or desktop

Including photos, cause description and action log

Automatic notification and escalation in the event of critical incidents

Complete documentation for

Better response times, clearer communication, less downtime

Standardized recording of information, faults and shift events

All relevant information and events are recorded and documented in digital reports. This can include, for example, faults, changes the driving style or quality and environmentally relevant information.

All information and events categorized and prioritized, which facilitates detailed research and analysis at a later date. at a later date.

In addition to the assignment of a Information to oner specific production plant, a machine or a piece of equipment, the exact time and optionally a duration recorded. This enables the evaluation of Service– and downtimes over a longer period of timeas well as the calculation of OEE key figures.

Freely definable text modules make input easier. You can also each entry file attachments (e.g. images, PDF documents etc.) can be added.

Examples of event categories:

- System failure

- Fault electrical

- Malfunction mechanical

- Malfunction quality relevant

- Disturbance uenvironmentalrelevant

- Standstill planned

- Standstill unplanned

- Near accident

- Observation of unsafe behavior

- etc.

Your solution for asset management

The right module

- Optimized for operators and service providers

- Centralized and detailed storage of technical documentation

- Mobile use via computer, tablet or smartphone

- Digitization and automation of manual routine work

- Integration of all internal stakeholders and

external service providers and contacts

KENEXOS® EAM

Asset inventory, IoT integration, maintenance and fault management, test equipment/spare parts management, asset history, life cycle, compliance management, helpdesk, photo documentation, reports

Documented shift handovers

A shift is completed by closing a shift reports is completed. Through an electronic signature or signature makes it possible to printing, signing and filing of shift reportsor handoverhandover logsare no longer necessary.

Users can set up notifications and download reports as a PDF documente by e-mailsent can be sent by e-mail.

The advantages of digital fault recording from KENEXOS®

Fast and mobile fault recording with offline-capable app

Clear and simple documentation of faults with photos and videos

Simple and standardized handover

Legally compliant documentation and storage

TEST FREE OF CHARGE

Choose KENEXOS® today

Test all functions

14 days free of charge without restrictions!

Use the app immediately

on the computer, tablet or smartphone

Completely risk-free

Your access ends automatically!